Best Tips About What Is Open Vs Closed Loop Code

Fuel System Open Loop Vs Closed At Monte Rodriquez Blog

Unlocking the Secrets of Open vs. Closed Loop Code

1. What's the Buzz About These Loops?

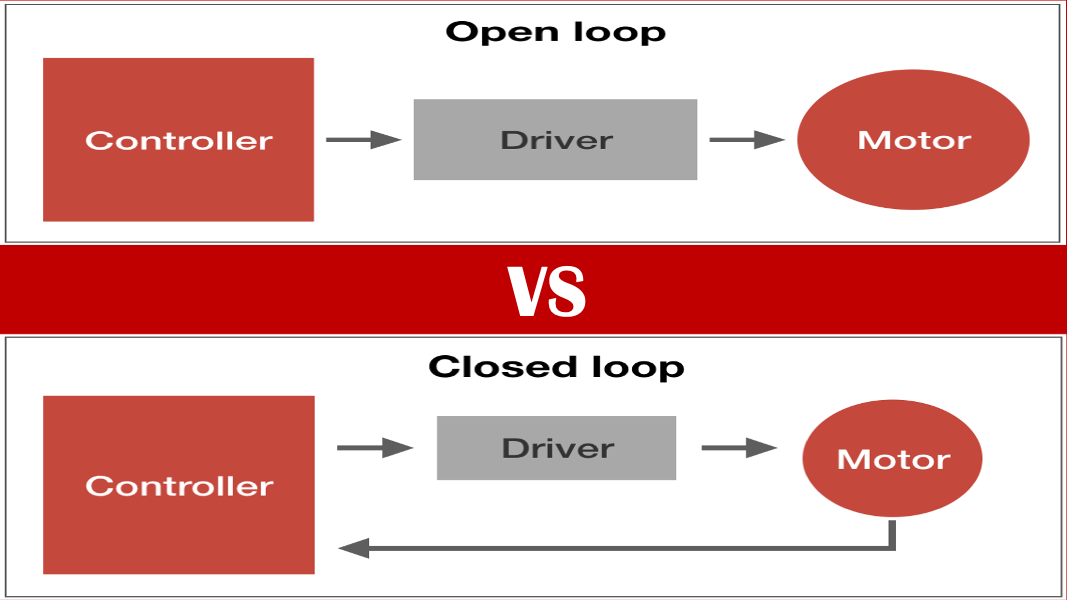

Ever wondered how software makes decisions? Or how your thermostat keeps your house at the perfect temperature? A lot of it boils down to different ways code is structured to handle information. One key distinction is between "open loop" and "closed loop" systems. Think of it like this: an open loop system is like following a recipe without tasting the food as you go, while a closed loop system is like tasting and adjusting the seasonings along the way to make it perfect.

In the world of coding, open loop code (noun phrase) operates based on pre-set instructions, without constantly checking the outcome. It's like setting your sprinkler system to water the lawn for 30 minutes every day, regardless of whether it rained or not. It blindly executes its task. While seemingly simple, this can be useful for repetitive tasks where feedback isn't crucial, or where gathering feedback would be too complex or costly.

On the other hand, closed loop code (noun phrase) is all about feedback. It constantly monitors the results of its actions and adjusts accordingly. It's like cruise control in your car. You set the desired speed, and the car constantly monitors its actual speed, making adjustments to the throttle to maintain the set point. It's reactive, and in many situations, more accurate.

So, in essence, open loop is "set it and forget it," while closed loop is "set it and constantly tweak it." Both have their place in the coding universe. Let's dive a little deeper, shall we?

Closed Loop System Vs Open ChristinakruwMacias

Open Loop Systems

2. When is "Hands-Off" a Good Thing?

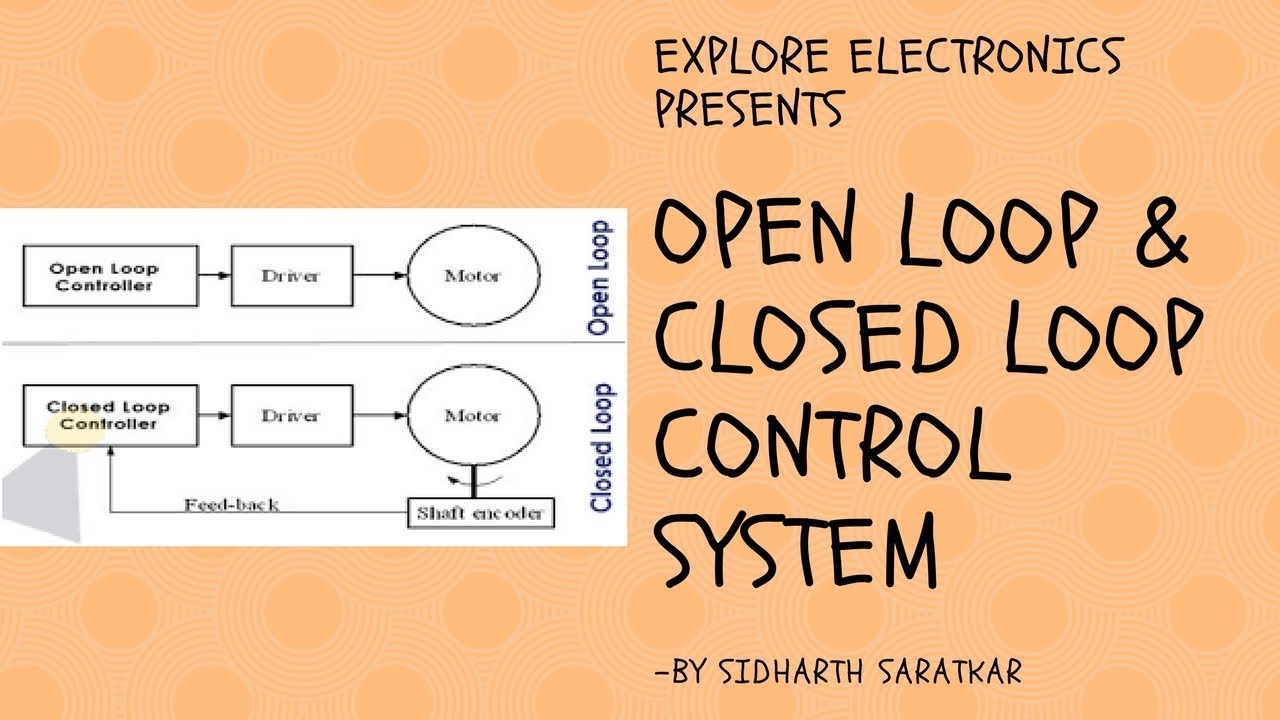

Okay, so imagine you're building a robot that needs to pick up a specific object. Using an open loop system, you would program the robot's arm to move a certain distance in a certain direction at a certain speed. The robot executes those instructions blindly, hoping that it will pick up the object. No sensors are involved; no confirmations are needed.

But, what if the object isn't exactly where you expected it to be? What if the floor is slightly uneven? The robot might miss the object entirely. That's the main drawback of open loop systems: they are susceptible to inaccuracies and disturbances. Their performance is directly tied to how well you initially calibrated them.

Despite this limitation, open loop systems are frequently used because they are simpler and cheaper to implement. They require fewer components (like sensors) and less complex code. They are perfect for well-defined tasks in controlled environments. For example, a simple timer in a microwave oven operates on an open loop principle. It runs for the set time, regardless of whether the food is cooked or not.

Think of it this way: you're making toast. With open loop, you set the toaster to "medium" and hope for the best. You're relying on the machine to consistently brown your bread the same way. Sometimes it works perfectly, sometimes you get charcoal. That's the open loop gamble!

Openloop Control System Vs Closedloop

Closed Loop Systems

3. Achieving Precision Through Feedback

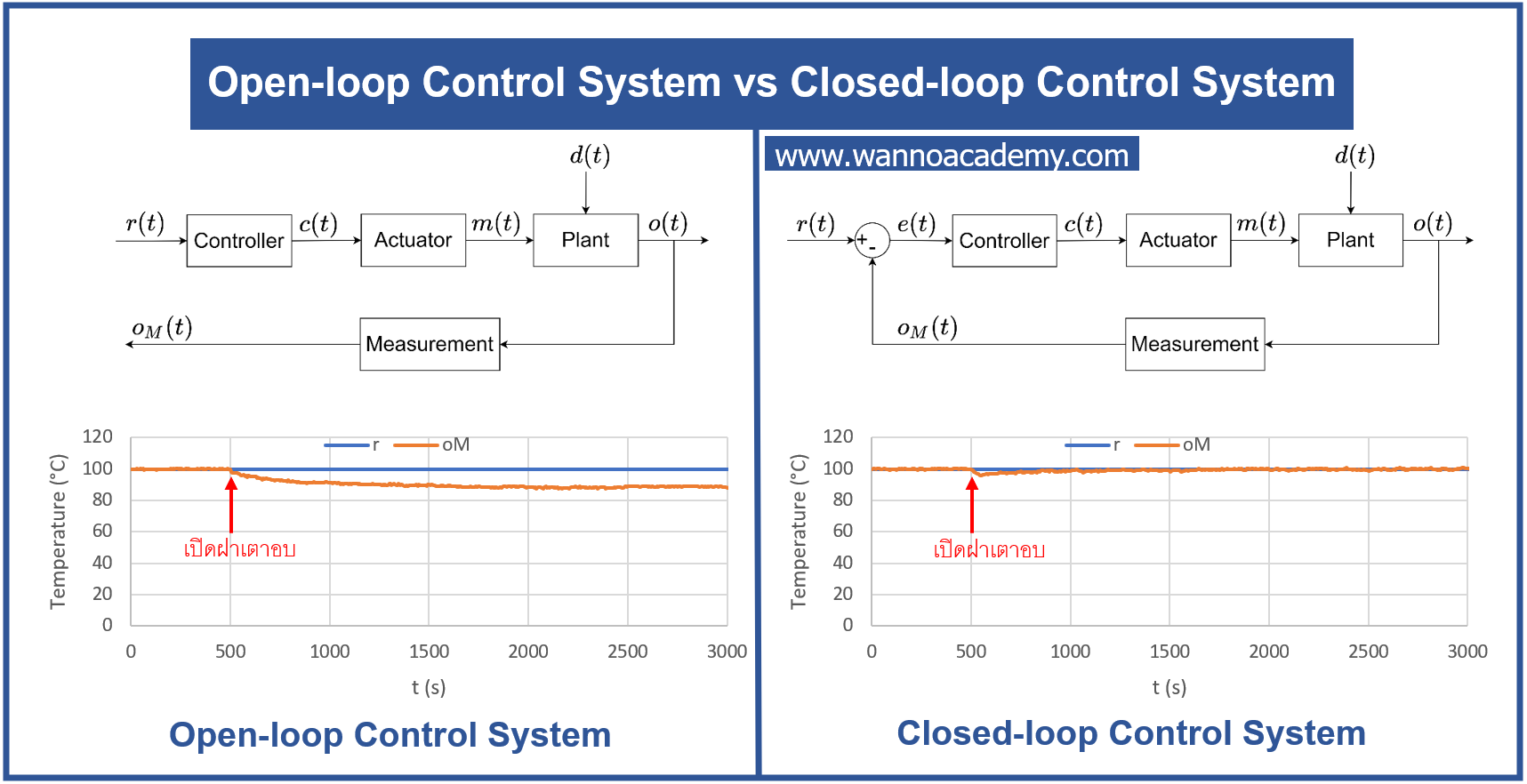

Now, let's revisit that robot arm example, but this time with a closed loop system. This time, the robot's arm has sensors that can detect the object's position and the force it's applying. The robot's code continuously monitors these sensors and adjusts the arm's movements to ensure it accurately grasps the object.

If the object is slightly out of place, the sensors will detect this, and the code will adjust the arm's trajectory. If the arm is applying too much force, the sensors will detect this, and the code will reduce the force. The system actively corrects itself to achieve the desired outcome. This makes closed loop systems much more robust and adaptable.

Consider an industrial oven maintaining a specific temperature. The oven's temperature is constantly monitored by a sensor, and the heating element is adjusted based on the difference between the desired temperature (the setpoint) and the actual temperature. If the temperature drops below the setpoint, the heating element is turned up. If the temperature exceeds the setpoint, the heating element is turned down. This constant feedback loop ensures the temperature stays within the desired range.

Going back to our toast analogy, imagine a toaster that can sense the browning level of the bread. It would automatically adjust the toasting time to ensure that your toast is perfectly browned every single time. No more burnt toast! That's the power of closed loop control. This method, of course, is usually more expensive and requires more programming, but in many applications, it's well worth it!

Weighing the Pros and Cons

4. Making the Right Decision for Your Project

The choice between open loop and closed loop control depends heavily on the specific application. Open loop systems are simpler, cheaper, and faster to implement. They are ideal for well-defined tasks in controlled environments where accuracy isn't paramount. Closed loop systems, on the other hand, offer superior accuracy, robustness, and adaptability. They are essential for applications where precision is critical and where disturbances are likely to occur.

Think about it this way: if you're controlling a simple LED light that just needs to turn on and off at specific times, an open loop system is perfectly adequate. But if you're controlling the flight of a drone, you absolutely need a closed loop system that can constantly monitor and adjust the drone's position and orientation.

In many real-world applications, a combination of open loop and closed loop control is used. For example, a robot might use an open loop system to move its arm to a general location, and then use a closed loop system to fine-tune its position and grasp the object. This hybrid approach leverages the strengths of both types of systems.

Ultimately, the best approach is the one that meets the specific requirements of your application while balancing cost, complexity, and performance. Consider the environment, the required accuracy, the potential for disturbances, and the available budget before making your decision.

Real-World Examples

5. From Everyday Gadgets to Industrial Automation

Open and closed loop systems are everywhere! From the simple machines we use every day to the complex systems that power industries, these control methods play a vital role in how things work. A basic household timer is a prime example of an open loop system. You set the time, and the timer runs until it reaches zero, regardless of what's actually happening.

On the other hand, consider the automatic braking system (ABS) in your car. ABS uses sensors to detect when the wheels are about to lock up during braking. If wheel lock is detected, the system modulates the brake pressure to prevent the wheels from locking, allowing you to maintain steering control. This is a classic example of a closed loop system at work.

Industrial automation relies heavily on both open and closed loop control. In a manufacturing plant, a conveyor belt might be controlled by an open loop system that moves the belt at a constant speed. However, a robotic arm picking parts off the conveyor belt would likely use a closed loop system to ensure accurate placement of the parts.

Even something as simple as a home thermostat uses closed loop control. It monitors the temperature in your home and adjusts the heating or cooling system to maintain the desired temperature. These loops are everywhere, quietly working to make our lives easier and more efficient.